Traffic cameras are engineered around predictable optical assumptions. They expect license plates to reflect light in a controlled and standardized way, allowing characters to be captured clearly within milliseconds. When a license plate film -https://lumiopix.com is introduced, those assumptions can shift in subtle but important ways.

Reflective films are not designed simply to block visibility. Instead, they modify how light is returned to a camera sensor during exposure. Under normal daylight, these materials may appear neutral. Under artificial illumination—especially infrared or flash-based systems—their behavior can diverge from what camera algorithms expect.

This divergence is the foundation of why reflective materials can change how traffic cameras react.

License Plate Cover and Optical Interaction with Flash Systems

A license plate cover has traditionally been understood as a physical barrier or protective layer. In modern applications, however, covers increasingly rely on optical engineering rather than thickness or tint. The goal is not concealment, but controlled interaction with camera illumination.

Traffic cameras often rely on short bursts of light to freeze motion and enhance contrast. When reflective materials respond differently to these bursts, the captured image can change dramatically. Light may scatter, return unevenly, or overwhelm the sensor.

Key optical responses that affect camera capture include:

-

overexposure during flash illumination

-

glare that reduces character edge definition

-

uneven reflection across the plate surface

-

sensor saturation in short exposure windows

These effects do not remove the plate from view but can reduce the clarity that automated systems rely on.

Anti Radar Film and Infrared-Based Camera Systems

An anti radar film is engineered specifically with artificial illumination in mind. Many modern traffic cameras operate in the infrared spectrum, using wavelengths invisible to the human eye. These systems assume that plate materials will reflect infrared light in a predictable pattern.

Reflective films challenge this assumption. By using layered or micro-structured designs, they alter how infrared light is reflected or scattered. Instead of returning light directly to the camera, the film may redirect it at non-optimal angles, reducing image contrast.

Factors influencing infrared interaction include:

-

wavelength sensitivity of the material

-

angle of incidence between camera and plate

-

intensity and duration of infrared emission

-

structural precision of the reflective layer

Because these variables differ between camera systems, results can vary—but the underlying principle remains consistent: altered reflection leads to altered interpretation.

Stealth Plate Cover vs Standard Reflective Surfaces

A stealth plate cover differs from a standard reflective surface not by how it looks, but by how it behaves under controlled lighting. Traditional license plates are designed to maximize legibility by retroreflecting light directly back to its source.

Stealth-oriented materials intentionally disrupt this process. Instead of clean retroreflection, they introduce directional reflection or scatter. This does not make the plate invisible, but it can interfere with how cameras isolate characters during capture.

Key distinctions between standard plates and stealth-oriented materials:

-

standard plates enhance contrast, stealth materials reduce it

-

conventional reflection is uniform, stealth reflection is directional

-

traditional surfaces assume steady lighting, stealth materials react to pulses

These differences explain why camera systems may struggle to interpret plates that behave outside their expected optical model.

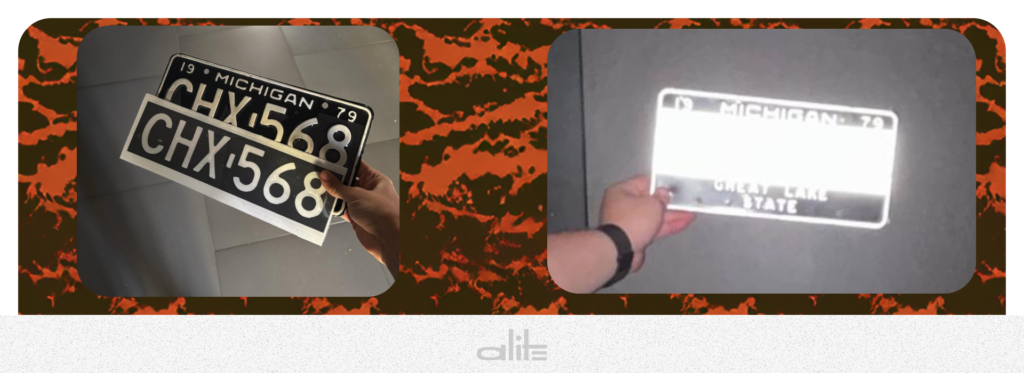

Infrared License Plate Cover Technology and Alite Nanofilm

An infrared license plate cover based on nanofilm technology represents a more refined approach to reflective control. Rather than relying on surface coatings alone, nanofilm structures operate at a microscopic level, interacting directly with specific light wavelengths.

Alite Nanofilm exemplifies this method. Its optical behavior is embedded within the material itself, allowing it to remain visually unobtrusive while still responding selectively to infrared and flash-based illumination. The material does not aim to block light, but to manage how it is returned during the camera’s exposure window.

Because the optical response is structural rather than superficial, performance remains stable over time. There is less reliance on coatings that can wear unevenly or degrade, resulting in more consistent interaction with camera systems.

Anti-Radar Stickers and the Future of Optical Mismatch

Anti-radar stickers highlight a broader trend in automotive materials: the move toward optical mismatch rather than physical obstruction. As camera systems become more advanced, materials that subtly alter reflection patterns can influence outcomes without changing everyday appearance.

This approach does not guarantee that a plate will always be misread. Instead, it increases the likelihood of variability in automated capture, particularly in systems heavily dependent on flash or infrared illumination.

As traffic cameras continue to evolve, the interaction between material science and sensor design will play an increasingly important role. Reflective films and nanofilm-based solutions demonstrate how small changes at the material level can have disproportionate effects on automated perception.

Why Reflective Materials Change Camera Reactions

When reflective materials change how traffic cameras react, the cause lies in physics, not illusion. A license plate film or anti radar film alters the fundamental interaction between light and surface during the critical moment of image capture.

Cameras are optimized for consistency. When that consistency is disrupted—through directional reflection, scatter, or infrared interaction—interpretation becomes less reliable. Concepts such as the stealth plate coveremerge from this gap between expectation and reality.

Technologies like Alite Nanofilm illustrate how advanced materials can exploit these dynamics with precision rather than brute force. As automated systems grow more complex, understanding how materials influence camera behavior will remain central to how license plates are perceived in a highly monitored environment.